Products Video

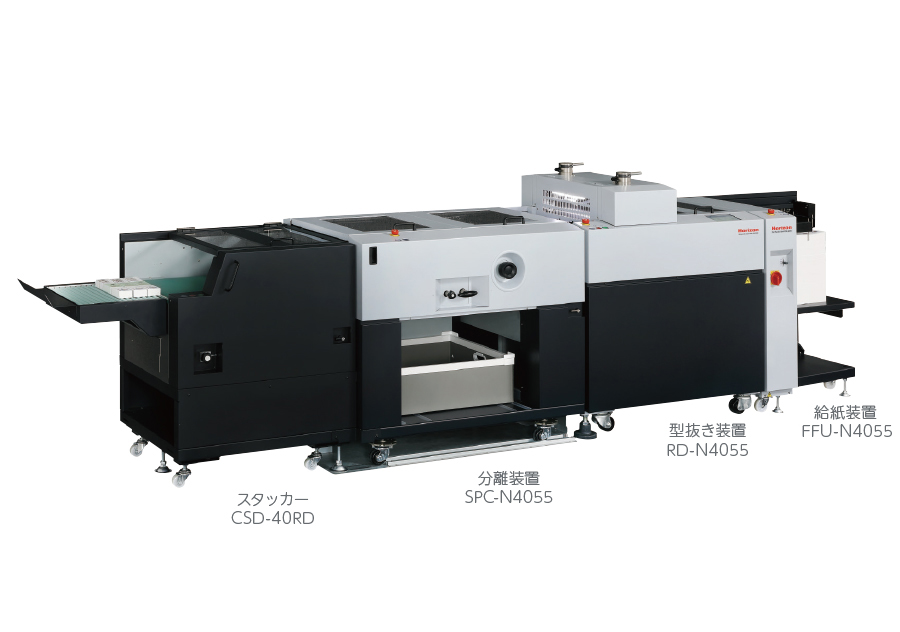

Efficient production with new separator and card stacker for labor saving operation.

HIGH EFFICIENCY – Die cutting, waste separation and stacking in one pass for efficient production.

APPLICATION FLEXIBILITY– Business cards, greeting cards, labels and light packages... A Wide range of applications can be processed.

HIGH PRODUCTIVITY – Maximum 6,000 sheets can be processed. In case of 21 up round corner business card application, it can process 126,000 cards.

| Model | RD-N4055 / RD-N4055DM |

|---|---|

| Sheet Feeding System | Air Suction Feed Belt |

| Sheet Size (Before processing) |

Max. W400 x L550 mm or W15.740" x L21.650" Min. W200 x L275 mm or W7.875” x L10.830” |

| Processed Material |

Normal paper, Coated paper, Cardboard The sheets below cannot be processed: Sheet whose back side is laminated (cover with polypropylene) Plastic fi lm |

| Material Thickness |

RD-N4055: 127.9 to 400 gsm Die Cutting: Max. 0.5 mm or 0.019” (In case of blade height: 0.8 mm or 0.031”) Max. 0.3 mm or 0.011” (In case of blade height: 0.6 mm or 0.023”) Creasing: Max. 0.4 mm or 0.015” (In case of blade height: 0.8 mm or 0.031”) RD-N4055DM: 127.9 to 400 gsm Die Cutting: Max. 0.5 mm or 0.019” Creasing: Max. 0.3 mm or 0.011” |

| Feeder Stack Height |

Maximum Feeder Stack Height: 500 mm or 19.68” Max Load: 100 kg or 220.5 lb |

| Die Size Upper Die |

Max. W400 x L560 mm or W15.748” x L22.047” Min. W160 x L100 mm or W6.30” x L3.937” |

| Upper Cutting Blade Height |

RD-N4055: 0.6 or 0.8 mm / 0.0236 or 0.0315” RD-N4055DM: 0.8 mm / 0.0315” |

| Production Speed |

Die cut roller 6,000 cycles per hour (When the ST-N4055 is connected, the number of processing sheet is 3,000 sheets per hour.) |